It can be difficult to get into the logistics industry. To get your first job, you might need to take extra classes or do some internships. The good news is that there are plenty of entry level logistics jobs available to help you get your foot in the door.

While most of these jobs require an associate's level degree, a bachelor's is highly desirable. This degree will allow you to understand how the supply chain works. You can also qualify for professional certifications by having a degree. Online classes are also available in specialized subjects. In certain cases, you might be eligible to get reimbursement for the cost of your graduate degree program.

A variety of industries can offer entry level logistics jobs. You can work in oil and gas production, aerospace manufacturing, or freight transport. You can also work internationally in many industries.

Logistics professionals draw on both their intellectual and physical abilities to solve problems. They are skilled at creating sustainable supply chains. They can influence both the executive as well as the operational decision-making processes. Although the job is challenging, it can also be rewarding. The logistics sector is experiencing rapid growth in a boom economy.

Logistics workers must have strong management skills and leadership qualities. They also need to be able to communicate effectively. They also need to be able use specialized software. They could also be responsible in finding storage space nearby shipping ports. They may also be responsible to make sure that the goods are cleared at customs.

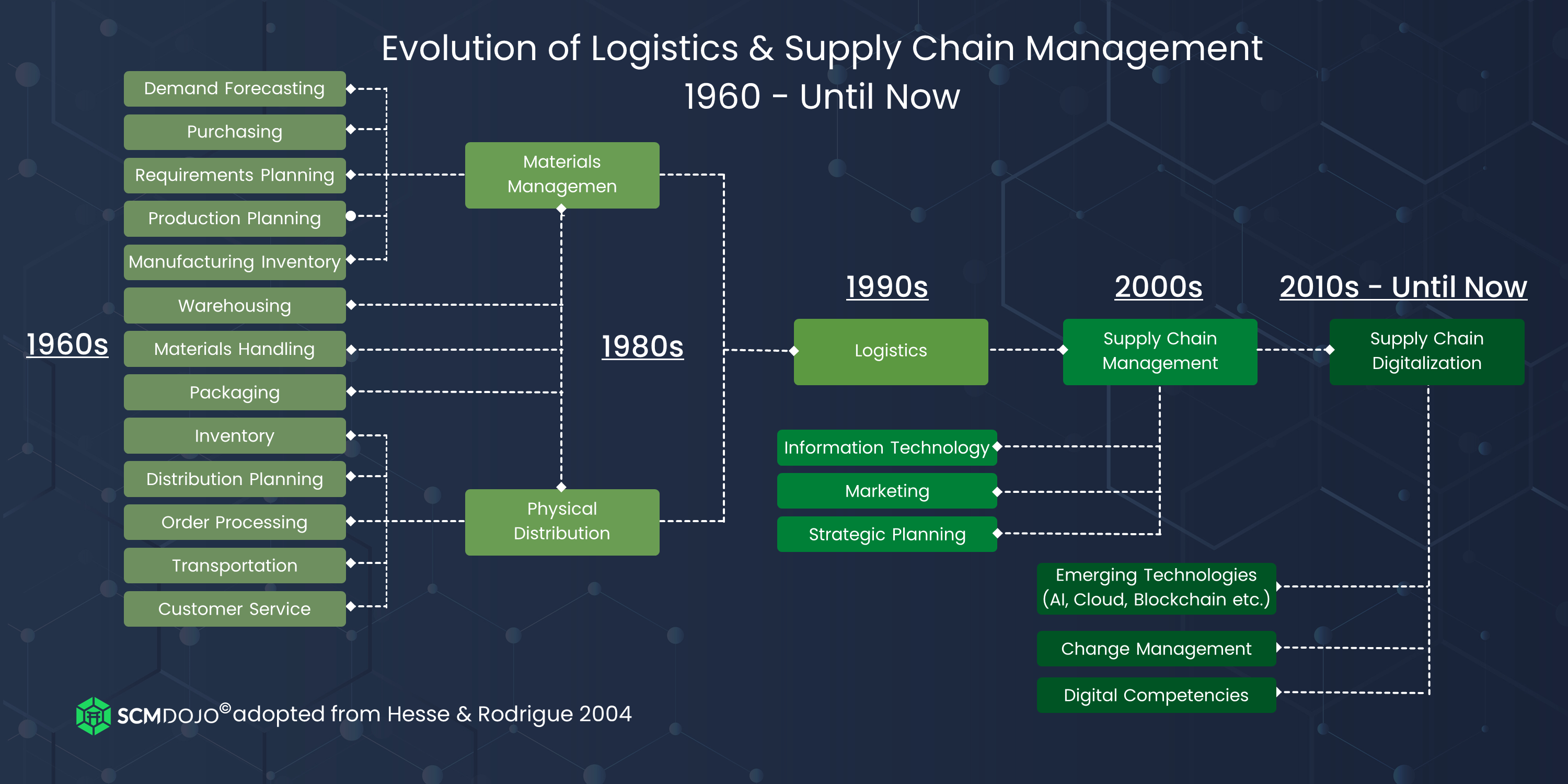

The logistics industry continues to evolve. New technologies and business models are changing the way the industry operates. Understanding these changes is important. You will be able to become a competent logistics professional with a bachelor's degree. You can also build a professional network. You can also attend industry conferences and seminars. You can also get your degree from an accredited institution.

You will also find a wide range of administrative jobs that require excellent communication and analytical skills. Some of these roles may be within the company itself, while others may involve customers, suppliers, or other business functions.

If you are looking to start a career in logistics, consider becoming a member of an industry association. These associations provide information about professional certifications as well as industry news and job listings. They may also help you to find a mentor. Many of these organizations offer graduate fellowships for students.

Many countries also offer vocational certifications that do not require prior logistics experience. These certifications are especially valued by enterprises with in-house transportation fleets. A Certificate of Professional Competence (Road Transport Operations) can also be obtained. This certificate is highly valued by companies with in-house fleets.

You can find entry level jobs in logistics all over the country. Job seekers can also use a number of online resources. For help, you can also tap into your family and friends.

FAQ

What is the distinction between Production Planning or Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. This is done through forecasting demand and identifying production capacities.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

Is automation important for manufacturing?

Automation is important not only for manufacturers but also for service providers. Automation allows them to deliver services quicker and more efficiently. In addition, it helps them reduce costs by reducing human errors and improving productivity.

Are there ways to automate parts of manufacturing?

Yes! Yes! Automation has existed since ancient times. The Egyptians invent the wheel thousands of year ago. Nowadays, we use robots for assembly lines.

In fact, there are several applications of robotics in manufacturing today. They include:

-

Automated assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing could also benefit from automation in other ways. 3D printing makes it possible to produce custom products in a matter of days or weeks.

What is the role of a production manager?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. A production planner ensures that the service and product meet the client's expectations.

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. No. It is important to know about the manufacturing processes in order to understand how logistics works.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

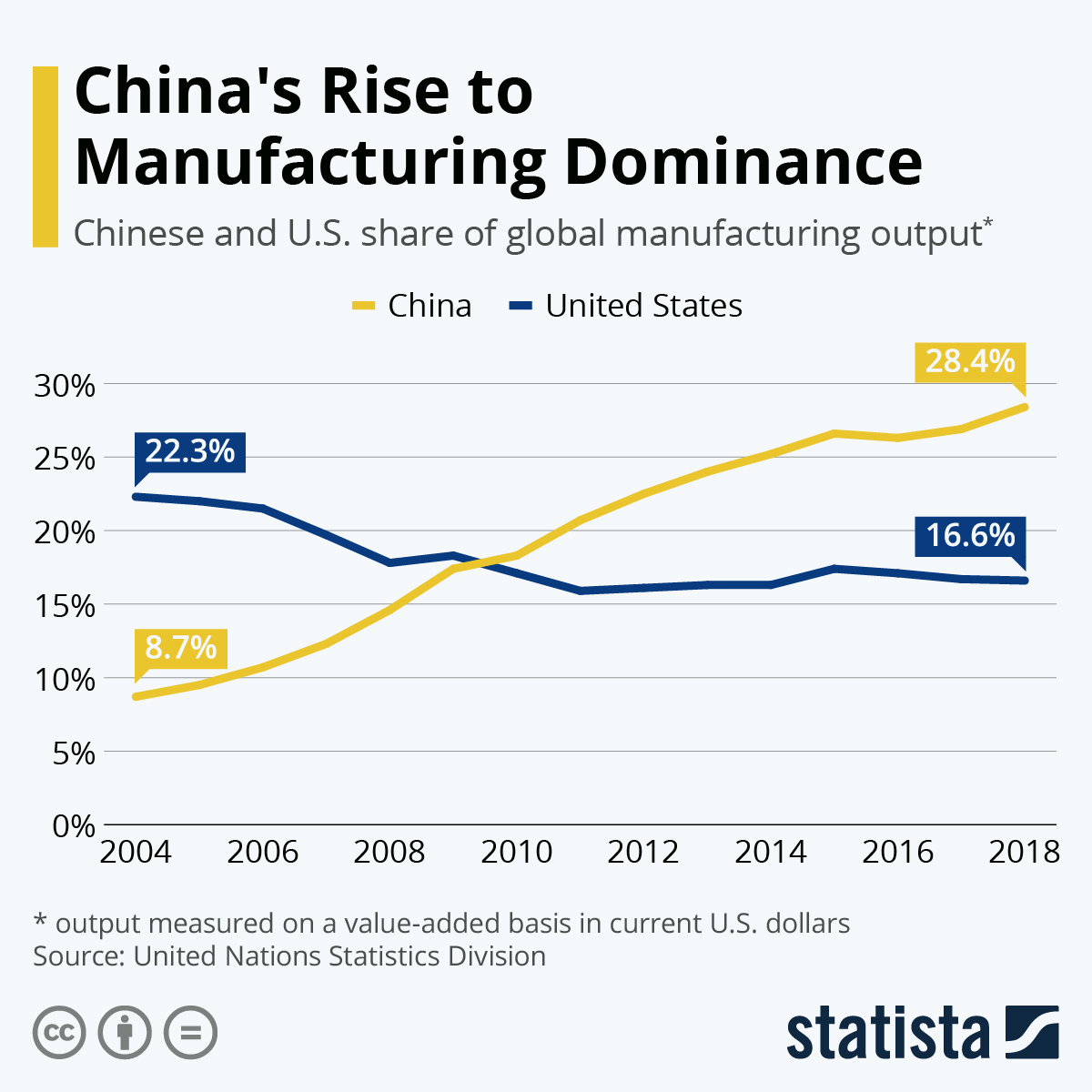

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. Many companies have adopted Six Sigma in recent years because they believe that there are no perfect products and services. The main goal of Six Sigma is to reduce variation from the mean value of production. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If this deviation is too big, you know something needs fixing.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you understand this, you can then identify the causes of variation. These variations can also be classified as random or systematic. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. Random variations would include, for example, the failure of some widgets to fall from the assembly line. However, if you notice that every time you assemble a widget, it always falls apart at exactly the same place, then that would be a systematic problem.

After identifying the problem areas, you will need to devise solutions. The solution could involve changing how you do things, or redesigning your entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they don’t work, you’ll need to go back and rework the plan.