The United States is experiencing a boom in manufacturing. The United State is now the third most important manufacturer in the globe. In Q1 2018, total manufacturing output reached a record $1.95 trillion and it is projected to reach that level by 2022. This is due in large part to automation and productivity gains.

High-Wage America institutes

High-wage work is a key component of the High Wage America Movement. The slow recovery of the United States from the Great Recession has been accompanied by high levels and low wages. However, there are solutions to the current low-wage crisis. The United States can improve its current workforce conditions by collaborating with states and other local stakeholders to develop a plan for high-wage positions.

The first step to implementing a sustainable production strategy is to create one. This involves a strategy to address issues such as wage stagnation, poor work conditions, and insufficient training. This can only be achieved if the United States fights unfair trade practices. It must also implement policies that help manufacturing communities prosper.

Automated manufacturing technologies

Automation technologies have transformed the way that we manufacture products, there is no doubt. Automated manufacturing technologies have drastically reduced costs and raised profits for companies and workers. Government policy in the USA is helping to make a difference by encouraging the advancement of new technologies. In fact, government policies can help businesses grow by encouraging the development of new technologies, and creating jobs in the process.

The US's first introduction of automated manufacturing was in the early 1900s when Ford Motor Company built its first car assembly line. This was the first of its kind in the world and greatly improved Ford's production rate. This reduced the time needed to assemble one car, which was previously 12 hours. It took only about 1 and a 1/2 hours.

Productivity growth

A number of factors point to productivity growth in manufacturing. There are large differences between the top-performing companies and those in the rest of the industry, which indicates that productivity growth is possible. Access to technology and mobility to move production is critical, as well as increased infrastructure investment. Productivity can be described as the sum of output and inputs. Most commonly, these are labor hours. Outputs can be measured in units produced, sales, or both.

The most commonly used way to measure productivity is labor productivity. This measure compares output to hours worked. The labor productivity measure can be broken down into different sectors, wages, or technological advancement. Profits of corporations are directly affected when productivity increases in the workplace. Employers who work more efficiently produce more output for every hour of their labor.

Outsourcing has a significant impact

There are many factors that impact outsourcing's effect on American manufacturing. In some cases, outsourcing can be a good thing. It will allow the country to compete in the global marketplace with countries with lower labor prices. Outsourcing can have the opposite effect and lead to the loss of American jobs. Sometimes, outsourcing can result in American jobs being replaced with foreign workers. Other times, it can lead American workers to earn lower wages.

Outsourcing started with American companies and then expanded to other countries. To reduce costs, some companies shirked all their core activities. Companies like Sodexo (which provides food service), IBM and UPS were all affected. Foxconn, which makes computers, started outsourcing. Apple is just one of many companies that outsource their entire manufacturing.

FAQ

What do you mean by warehouse?

A warehouse is an area where goods are stored before being sold. It can be either an indoor or outdoor space. In some cases it could be both indoors and outdoors.

How important is automation in manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. Automation allows them to deliver services quicker and more efficiently. It helps them to lower costs by reducing human errors, and improving productivity.

How can efficiency in manufacturing be improved?

The first step is to identify the most important factors affecting production time. We must then find ways that we can improve these factors. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you have identified the factors, then try to find solutions.

Are there ways to automate parts of manufacturing?

Yes! Yes. The Egyptians created the wheel thousands years ago. Nowadays, we use robots for assembly lines.

Robotics is used in many manufacturing processes today. They include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing could also benefit from automation in other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

What are the logistics products?

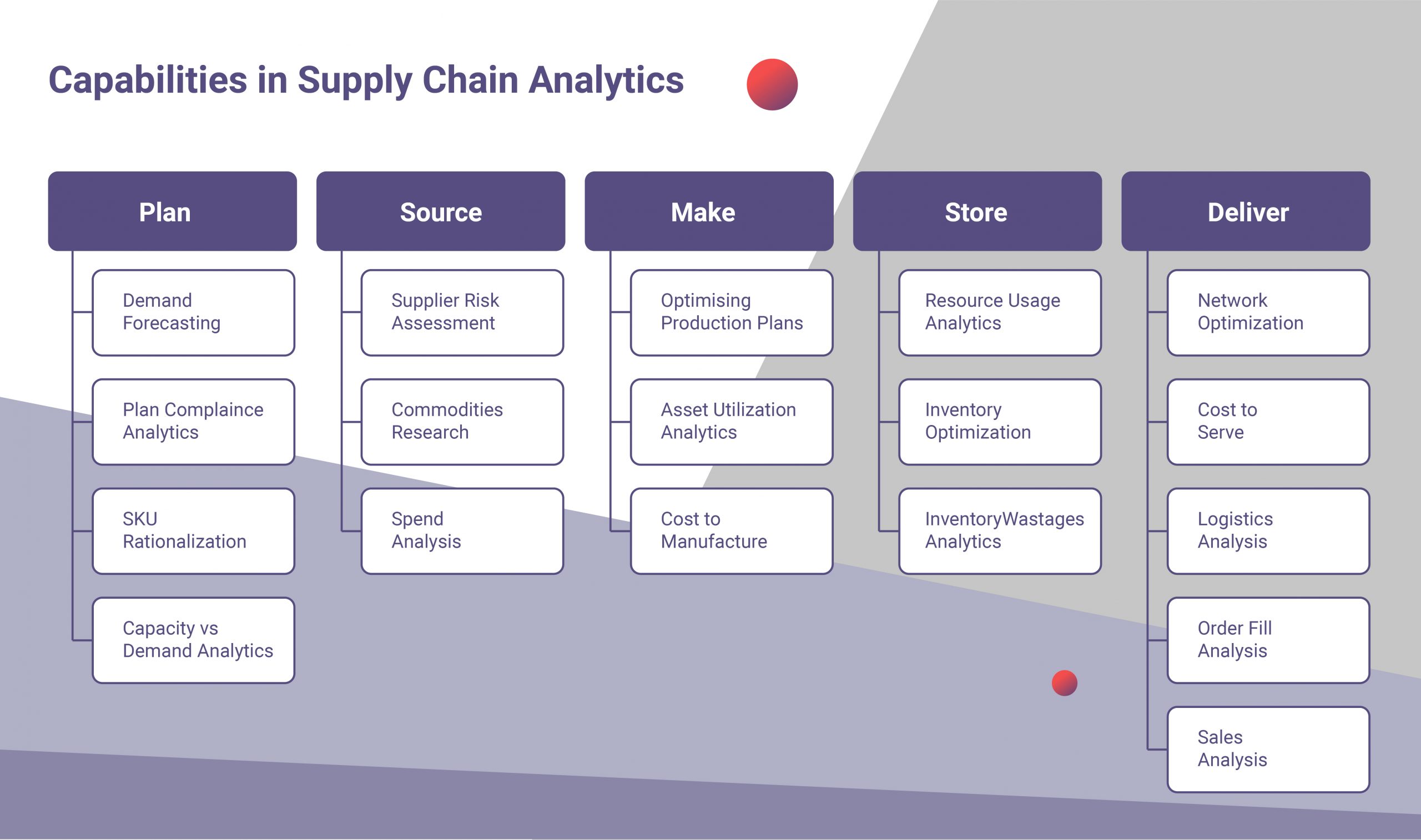

Logistics refers to the movement of goods from one place to another.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure the product reaches its destination in the most efficient manner. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What are the four types of manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

What is production planning?

Production Planning includes planning for all aspects related to production. This document is designed to make sure everything is ready for when you're ready to shoot. It should also contain information on achieving the best results on set. This information includes locations, crew details and equipment requirements.

The first step is to outline what you want to film. You may have already chosen the location you want, or there are locations or sets you prefer. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. You might decide you need a car, but not sure what make or model. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you have selected the car you want, you can begin to think about additional features. Are you looking for people to sit in the front seats? Or perhaps you need someone walking around the back of the car? Perhaps you would like to change the interior colour from black to white. These questions will help guide you in determining the ideal look and feel for your car. The type of shots that you are looking for is another thing to consider. You will be filming close-ups and wide angles. Maybe you want the engine or the steering wheels to be shown. All of these things will help you identify the exact style of car you want to film.

Once you have determined all of the above, you can move on to creating a schedule. You will know when you should start and when you should finish shooting. The schedule will show you when to get there, what time to leave, and when to return home. Everyone will know what they need and when. Hire extra staff by booking them ahead of time. You should not hire anyone who doesn't show up because of your inaction.

You will need to factor in the days that you have to film when creating your schedule. Some projects are quick and easy, while others take weeks. When creating your schedule, be aware of whether you need more shots per day. Shooting multiple takes over the same location will increase costs and take longer to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budget setting is an important part of production planning. It is important to set a realistic budget so you can work within your budget. Keep in mind that you can always reduce your budget if you face unexpected difficulties. However, it is important not to overestimate the amount that you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many businesses are now using lean manufacturing to improve their competitiveness. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types in lean manufacturing

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. It is better to repair a part than have it removed from the production line if it needs to be fixed. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. It involves continuous improvement of processes, people, and tools.