Lean thinking can be used to improve the performance of your organization. It involves eliminating wastes and unvalued activities from your processes. It is also an opportunity to create a lean organization culture. A lean culture is a collection of values, principles and practices that increase employee morale and quality and improve productivity. It creates a more sustainable work environment.

Lean thinking starts with identifying value for your customers. This means understanding your customers' needs and the whole value chain. Once you know what your customers need, you can identify which steps are involved in your processes. You can identify the steps involved in each process to help you determine whether your current processes are efficient. To see how your business is operating, you can also use value streaming mapping. The value stream map shows the flow of your business, how it works, and the value created by each process.

Lean thinking demands flow. It is the ability of switching quickly between activities. This is particularly important for responding to customer demands. It reduces backlogs and inventory. It allows workers the ability to quickly switch between tasks.

Lean organisations have an equal approach when it comes to managing output. They encourage collaboration and clear communication. They promote quality assurance and celebrate their successes. They reduce unnecessary costs to customers and suppliers.

Lean thinking is a continuous process. It can be applied in any kind of work. It can help reduce environmental damage, reduce waste, and improve employee morale. Although lean thinking is often used in manufacturing, it can be used in all areas of business.

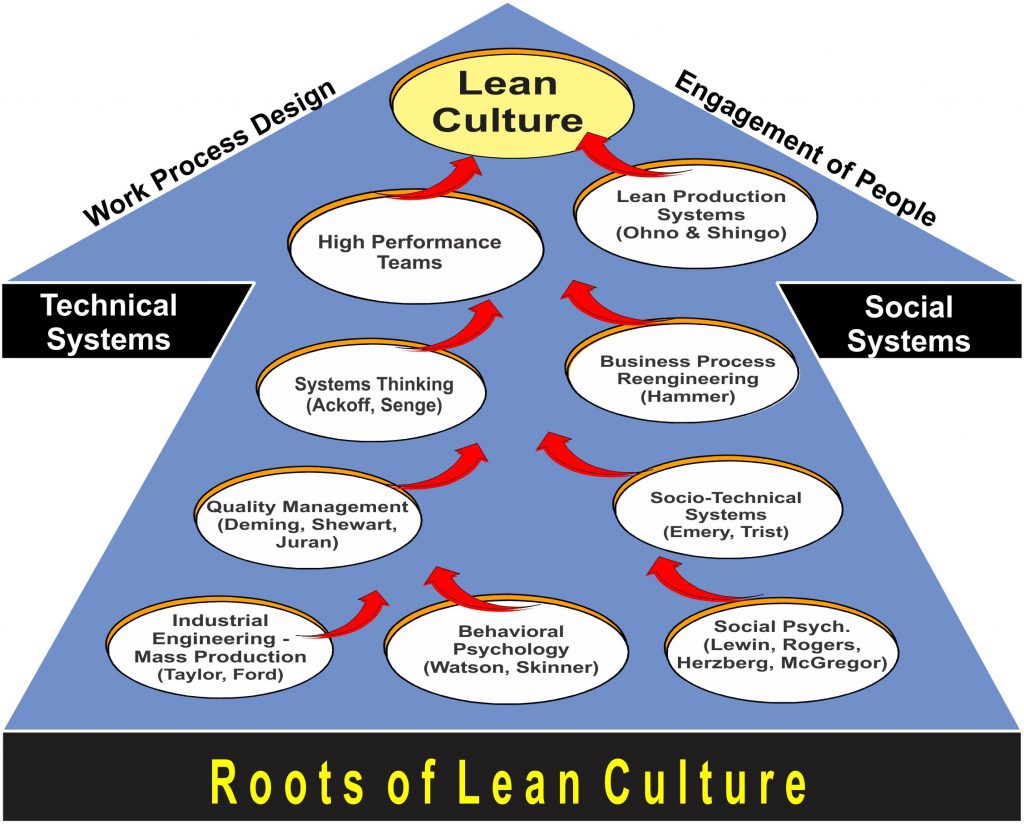

Creating a culture that fosters lean thinking is a key factor in implementing lean production practices. The culture should be based on a clear definition of value, constant improvement, and employee motivation. You must also be willing to make small, incremental improvements on a regular basis. This is called Kaizen.

Lean thinking is continuous improvement. It requires a kaizen spirit. To improve the product's quality, you should be open-minded to making small improvements daily. You can do this by making changes in the company or using standardized work. A standardized work describes a graphic description of a smooth flow of work. Everything is clearly located. It helps people see how to overcome obstacles and make work easier.

Other production metrics should also be considered when you implement lean production techniques. For example, the ratio of downtime to running time shows how often an asset is available for production. It also displays how often planned maintenance is necessary. The ratio of quality materials is an indicator of how well a supplier delivers high-quality products.

Also, it is important to understand the risks associated with the "Just In Time" principle. This principle guarantees that supplies will be delivered in a timely manner. It helps focus and concentrate the mind to the task at hand. It can also lead to problems within the industry.

FAQ

What does the term manufacturing industries mean?

Manufacturing Industries refers to businesses that manufacture products. Consumers are the people who purchase these products. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. These companies produce goods using raw materials and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What are the 7 Rs of logistics?

The acronym 7R's of Logistic is an acronym that stands for seven fundamental principles of logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The acronym consists of the following letters:

-

Responsible - ensure that actions are in compliance with legal requirements and do not cause harm to others.

-

Reliable - Have confidence in your ability to fulfill all of your commitments.

-

Reasonable - use resources efficiently and don't waste them.

-

Realistic – consider all aspects of operations, from cost-effectiveness to environmental impact.

-

Respectful - treat people fairly and equitably.

-

Resourceful - look for opportunities to save money and increase productivity.

-

Recognizable provides value-added products and services to customers

How can manufacturing excess production be decreased?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. By doing this, we could free up resources for other productive tasks.

A Kanban system is one way to achieve this. A Kanban Board is a visual display that tracks work progress. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state represents an individual priority level.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. It is possible to keep a task in the beginning stages until it gets to the end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. Managers can view the Kanban board to see how much work they have done. This information allows managers to adjust their workflow based off real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing is about eliminating waste from all stages of the production process. Anything that does nothing to add value to a product is waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Exceed materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

What does it mean to warehouse?

A warehouse is an area where goods are stored before being sold. It can be indoors or out. It could be one or both.

What are manufacturing and logistics?

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma aims to reduce variation in the production's mean value. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If you notice a large deviation, then it is time to fix it.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you understand that, it is time to identify the sources of variation. This will allow you to decide if these variations are random and systematic. Random variations happen when people make errors; systematic variations are caused externally. Random variations would include, for example, the failure of some widgets to fall from the assembly line. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you identify the problem areas, it is time to create solutions. That solution might involve changing the way you do things or redesigning the process altogether. You should then test the changes again after they have been implemented. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.