Are you looking for a job in industrial engineering? Read on to discover what types of jobs are available. We'll be discussing the types of jobs and the average salary. We'll also talk about the skills needed and where to find these jobs. You can then apply for the job that appeals to you the most! Good luck! Before you apply for an industrial engineering job in the future, be sure to read through the job description.

Job description

Industrial engineers aren't for everyone. It involves applying engineering principles and technology to improve company production processes. This engineer is responsible to develop tools and analytics that allow companies to monitor their costs and schedules. He or she also reviews production data to determine areas for improvement and compiles equipment and material lists, as well as cost analyses, production cost estimations, and purchase orders before implementing new projects.

An industrial engineer job requires a degree of mechanical engineering. This field requires a broad knowledge of engineering principles and practices, as well as a knack for problem-solving. An industrial engineer is often required to integrate technical knowledge with a deep understanding of human capabilities. Industrial engineers should be well-organized, have strong analytical abilities, and communicate well. They are responsible for improving the production process in companies and managing factories and warehouses.

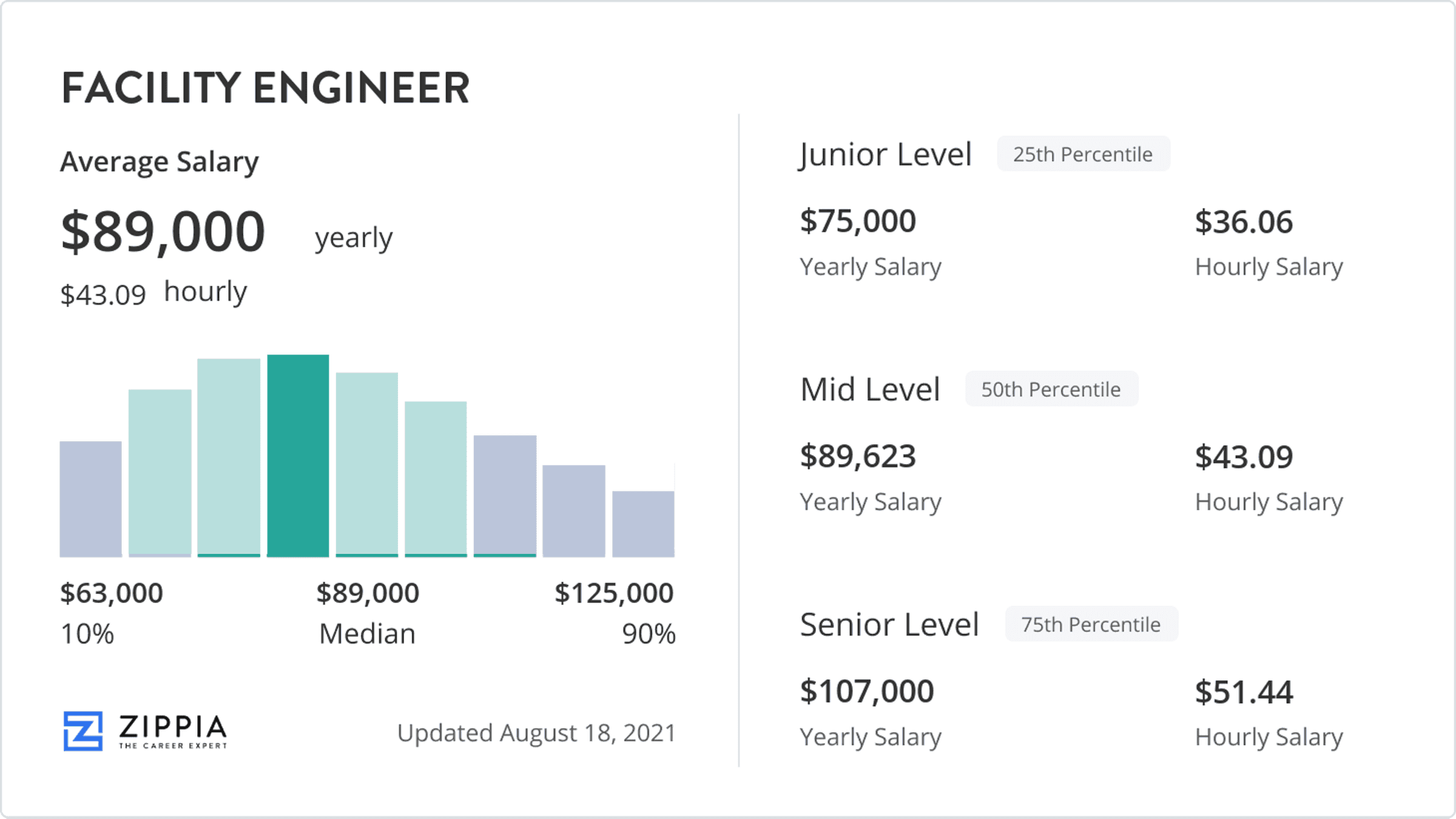

Salary range

The range of salaries for industrial engineers depends on experience. Starting salaries are around $85,000, but the amount of compensation can go up to $100,000. The following table explains the salary range for industrial engineers by experience level. Ventura, California's Entry Level Engineer, can expect to make $86,000 per a year. For experienced Industrial Engineers, the range of salary is $85,000 to $100,000. You can also get hired as a Project Engineer, which typically requires a four-year degree.

The average salary of an Industrial Engineer will vary depending on the location and industry. In New York, industrial engineers can expect to earn from $60,700 to $140,000 annually. While it's difficult to identify the upward trend of salaries, the national averages have increased over 40% in the last 10 years. This trend is expected to continue. Monster's Salary Tools will give you more information on the range of salaries in your area.

Education required

Industrial engineers do not normally need licensing, although it may be a prerequisite for government contracts. Industrial engineers don't need licensing for entry-level positions. They must have relevant work experience, and a degree from an approved institution to be eligible for professional licensure. Most industrial engineers work in offices, factories, or labs. Many industrial engineers work in the aerospace and engineering industries, as well as in medical and control instrument manufacturing.

Many industrial engineers prefer to work as interns in their college years. This is a great way to gain valuable experience. Industrial engineering jobs at entry level don't require any professional experience. However, having more experience in engineering can give you an advantage over your competitors. Internships can be very valuable if your goal is to work in government or another organisation. Additionally to internships and security clearance, industrial engineers may also require it.

Locations

You can find many jobs in industrial engineering that are highly rewarding. The most common entry-level tasks in this field include completing calculations, testing and monitoring devices, and documenting results. They may also assist in the creation of budgets and tracking metrics. Industrial engineers may need to stand for long periods of work. Industrial engineers must be able to effectively communicate. In some cases, they work under the supervision of a more senior engineer.

Industrial engineers assist companies in creating efficient production processes that use as little energy and resources as possible. Their primary objective is to maximize efficiency and reduce costs while maintaining high labor productivity. Industrial engineers can be found in offices and factories. They are responsible for improving the operation of companies. A bachelor's degree or equivalent in industrial engineering is required to be eligible for entry-level jobs in industrial engineering. The Bureau of Labor Statistics predicts that the median income for industrial engineers in 2021 will be $95,300.

FAQ

How can I find out more about manufacturing?

Hands-on experience is the best way to learn more about manufacturing. But if that is not possible you can always read books and watch educational videos.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

What skills are required to be a production manager?

Being a production planner is not easy. You need to be organized and flexible. Also, you must be able and willing to communicate with clients and coworkers.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

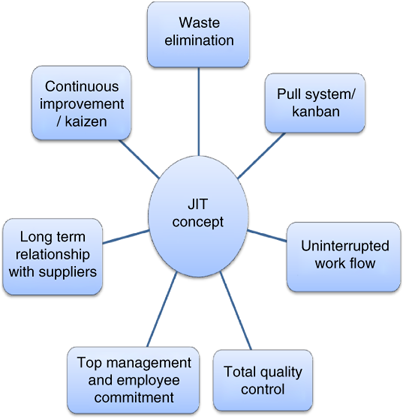

How to Use Six Sigma in Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. Many companies have adopted Six Sigma in recent years because they believe that there are no perfect products and services. Six Sigma's primary goal is to reduce variation from the average value of production. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you have a good understanding of the basics, you can identify potential sources of variation. This will allow you to decide if these variations are random and systematic. Random variations happen when people make errors; systematic variations are caused externally. You could consider random variations if some widgets fall off the assembly lines. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. It might mean changing the way you do business or redesigning it entirely. After implementing the new changes, you should test them again to see if they worked. If they don't work, you will need to go back to the drawing boards and create a new plan.