A Chemical Technician can be described as an artisan that is involved with the production of chemical products. The technician is responsible for testing the materials used in manufacturing. They can work in laboratories, on manufacturing lines, or in research and development.

They are typically supervised and assisted by chemists. They monitor the product's quality, test new materials, and collect samples. They might be promoted after they have gained experience. Many pharmaceutical companies hire them. A bachelor's degree in engineering, biology, and chemistry can help you earn more.

While the pay for a Chemical Technician varies greatly by region, the average salary for this position is $48,990. This includes taxable wages as well as bonuses. It also covers the education, skills and experience of the worker. Chemical Technicians making more than $60,000 a year were the most highly paid.

One of the duties of a Chemical Technician is to conduct research and develop chemicals and pharmaceuticals. These technicians analyze the ingredients of medicines, food, and other products. They can also supervise workers on the production line.

You will need an associate's/bachelor's degree to be a Chemical Technician. A graduate or doctoral degree is also possible. Some companies prefer to hire chemical technicians who have a college degree. You may need a master's in order to work in other fields.

Visit a school placement office to get information about possible employment opportunities. You can also search the Internet for job banks. Another good resource is the American Chemical Society. Local chapters can often post job listings.

If you're looking for a job as a Chemical Technician, you should be prepared to work long hours. Although most laboratories work seven days a week, experienced workers may be called in for odd-hours inspections and experiments.

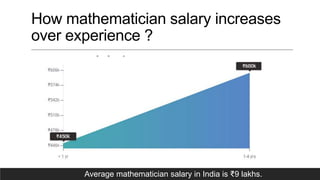

Most of the Chemical Technicians' salaries range between $36,000 and $47,000. For experienced workers, the average salary is $11,000. Entry-level workers on the other side can earn between $15-18 an hour.

San Francisco and San Jose are the most highly ranked cities in the United States for Chemical Technician salaries. Both cities beat the national average by over 20 percent. In addition, the BLS reported that Chemical Technicians in these areas earned more than $83,600.

According to the Bureau of Labor Statistics (Bolster of Labor Statistics), Chemical Technicians will see slower job growth than the average. Their employment is expected grow by 3 per cent through 2014. However, the number and quality of jobs for Chemical Technicians will decrease by only 4 per cent over the next ten-years. It is likely that skilled technicians will be in high demand because of this.

Chemical R&D will be in high demand as environmental issues continue to grow. The best jobs for these workers will be found in laboratories that perform testing on new materials.

FAQ

Do we need to know about Manufacturing Processes before learning about Logistics?

No. It doesn't matter if you don't know anything about manufacturing before you learn about logistics. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

Is automation necessary in manufacturing?

Automation is essential for both manufacturers and service providers. It allows them to offer services faster and more efficiently. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What are the essential elements of running a logistics firm?

You need to have a lot of knowledge and skills to manage a successful logistic business. To communicate effectively with clients and suppliers, you must be able to communicate well. You should be able analyse data and draw inferences. You must be able manage stress and pressure under pressure. To increase efficiency and creativity, you need to be creative. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

How can efficiency in manufacturing be improved?

First, determine which factors have the greatest impact on production time. We must then find ways that we can improve these factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you've identified them, try to find solutions for each of those factors.

What is the difference between manufacturing and logistics

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What is the role of a production manager?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. They also ensure the quality of the product and service meets the client's requirements.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use the Just-In-Time Method in Production

Just-intime (JIT), which is a method to minimize costs and maximize efficiency in business process, is one way. It's the process of obtaining the right amount and timing of resources when you need them. This means that you only pay for what you actually use. Frederick Taylor, a 1900s foreman, first coined the term. He observed how workers were paid overtime if there were delays in their work. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. You won't have to pay more for unnecessary items.

There are many JIT methods.

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will allow you to track how much material you have left over after using it. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based : You can stock the materials you need in advance. This allows you predict the amount you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. If you know the amount you require, you can buy the materials you need.

-

Resource-based: This is the most common form of JIT. You assign certain resources based off demand. If you have many orders, you will assign more people to manage them. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This is similar to cost-based but instead of looking at individual workers' salaries, you look at the total company price.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based JIT: A variation on resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based: This is one of the newest forms of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It reduces lead times and improves throughput.