Industrial engineering (wvu) is the study that people, machines, equipment, information and energy work together to create products or services. It is concerned with increasing productivity, reducing costs, improving the quality, and maintaining an environment that is safe.

West Virginia engineers can find work in a wide range of industries. Engineers in West Virginia use their expertise in design, production and operation to solve issues for all types of organizations and businesses.

Unlike other types of engineering, industrial engineering focuses on the big picture: the relationship between people, systems and the "right" combination of resources to produce products or services that meet or exceed customer expectations. The discipline is broad and requires both technical as well as interpersonal skills.

Professionals in the field of management bridge the gap from management to operations. They motivate employees, and also determine which tools and software should be utilized and how. They work with computers and sophisticated software to ensure that all systems function properly, ensuring productivity, reliability, schedule adherence, and cost control.

Students can use the knowledge, skills, and abilities of mathematics, statistics, engineering, management, and physics to analyze processes, design equipment, and produce services or products. The projects can involve mechanical, electronic, or computer equipment.

College graduates with industrial engineering experience often find they have an advantage over their peers in the job market. They could get a higher wage, more responsibility and a better balance between work and life.

Students who are enrolled in college can get valuable work experience through co-op programs. They are usually with local manufacturers but they can also be found at banks, insurance companies, construction firms, and public utilities.

The University of West Virginia's co-op programme provides students with real-world engineering experience. The experiences can include inspecting construction sites, calculating materials and taking part in field reviews.

Students can also get valuable work experience through internships on industrial projects. It's a great opportunity to gain experience in the engineering industry and develop important connections with potential employer.

Graduates are eligible to sit for the licensure exam to become a professional engineer in WV. It is a good way to improve your resume and stand out amongst the competition.

Choosing the right program for your interests and career goals is crucial to success in this industry. The University of West Virginia's industrial engineering program can be tailored to meet your requirements.

A bachelor's is the standard requirement for industrial engineering careers, but some colleges or universities offer graduate-level degrees. These programs are usually several years long and designed to prepare students to pursue advanced studies or careers in industrial engineering.

The University of West Virginia awards a bachelor's in industrial engineering as well as a number of master's degrees. These programs will prepare students to enter careers in industrial technology and to take on leadership roles in business. These programs are accredited by the Accreditation Board for Engineering and Technology (ABET), Inc.

FAQ

What are the 7 R's of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was developed by the International Association of Business Logisticians (IABL) and published in 2004 as part of its "Seven Principles of Logistics Management" series.

The acronym is made up of the following letters:

-

Responsible – ensure that all actions are legal and don't cause harm to anyone else.

-

Reliable: Have faith in your ability or the ability to honor any promises made.

-

Be responsible - Use resources efficiently and avoid wasting them.

-

Realistic – consider all aspects of operations, from cost-effectiveness to environmental impact.

-

Respectful - show respect and treat others fairly and fairly

-

Responsive - Look for ways to save time and increase productivity.

-

Recognizable: Provide customers with value-added service

What does warehouse mean?

A warehouse is a place where goods are stored until they are sold. It can be an outdoor or indoor area. Sometimes, it can be both an indoor and outdoor space.

How important is automation in manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. It allows them provide faster and more efficient services. In addition, it helps them reduce costs by reducing human errors and improving productivity.

What skills should a production planner have?

You must be flexible and organized to become a productive production planner. You must also be able to communicate effectively with clients and colleagues.

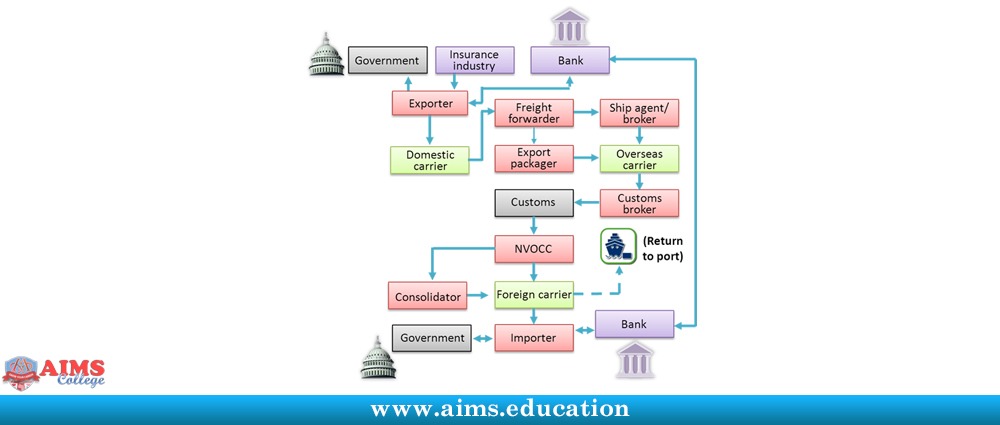

What kind of jobs are there in logistics?

There are different kinds of jobs available in logistics. Some examples are:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers, - They sort out and pack freight in warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents - They purchase goods and services needed for company operations.

-

Customer service representatives are available to answer customer calls and emails.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

How can efficiency in manufacturing be improved?

First, identify the factors that affect production time. Next, we must find ways to improve those factors. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you identify them, look for solutions.

What are my options for learning more about manufacturing

You can learn the most about manufacturing by getting involved in it. If that is not possible, you could always read books or view educational videos.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation developed the 5S method in 1954. It improves the work environment and helps companies to achieve greater efficiency.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Through these actions, workers can perform their jobs more efficiently because they know what to expect from them.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action to increase efficiency. By sorting, for example, you make it easy to find the items later. When you arrange items, you place them together. You then organize your inventory in groups. You can also label your containers to ensure everything is properly labeled.

Employees must be able to critically examine their work practices. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. They must learn new skills and techniques in order to implement the 5S system.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They will feel motivated to strive for higher levels of efficiency once they start to see results.