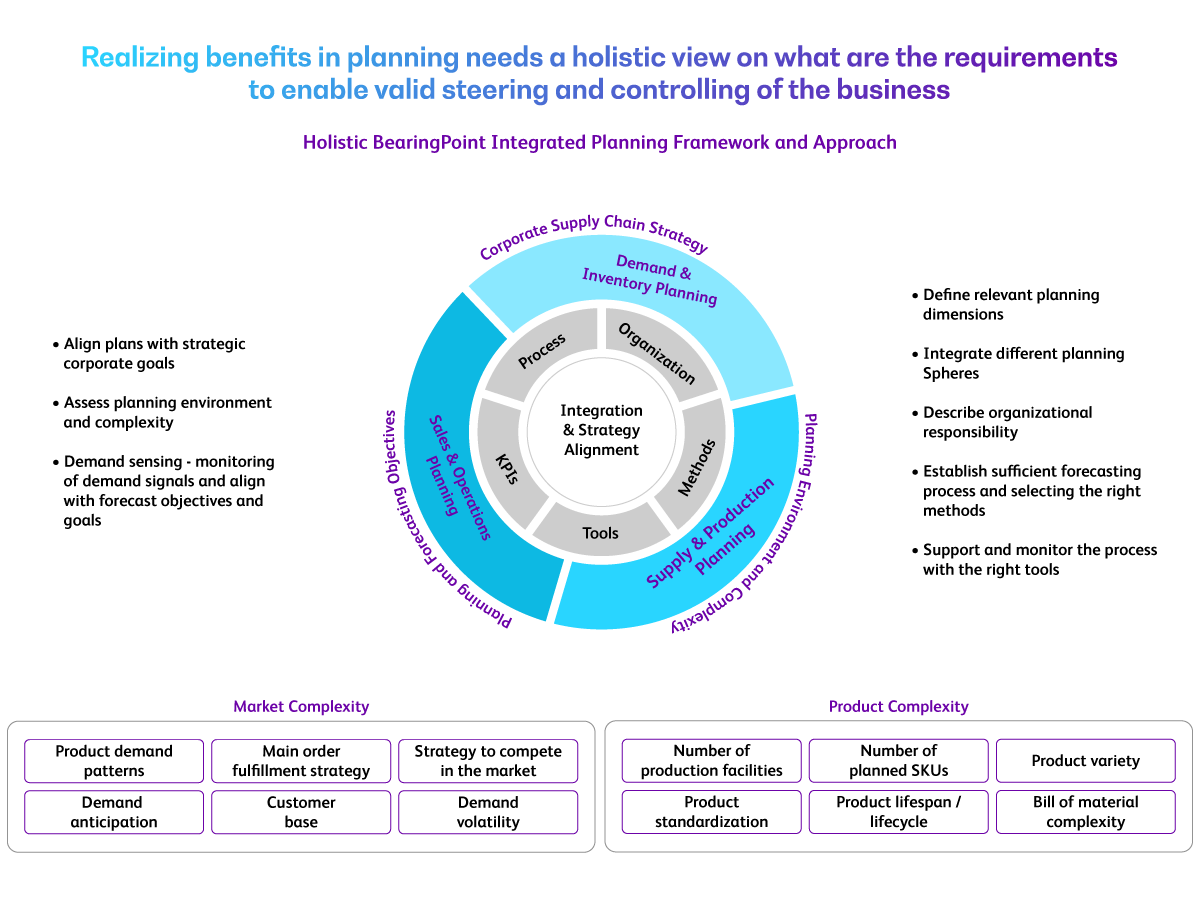

Demand management can be described as a strategy to make sure that a company is meeting its customers' demands. In essence, it involves bridging the gap between marketing and supply, by enabling organizations to predict demand. This process can increase speed and quality of delivery and reduce invoice disputes. It also lowers the cost of running a business.

Companies that have a robust demand management process are more open to market changes. This is because they have a system in place to identify the ideal customer, which can lead to effective marketing.

Businesses can use demand management to plan for future demand and improve customer satisfaction. It can be used to reduce disputes over invoices and maximize asset utilization if done correctly. A proper demand management strategy can also improve operational flexibility and operational resiliency.

Project management software can help improve demand management. This software helps teams coordinate their work and prevents silos. Companies can quickly correct supply chain problems by creating a change management program.

ILOG's PowerOps Suite integrates scheduling functions for manufacturing. Dynasys and QAD also offer applications to help organizations plan and create a demand/supply strategy. These applications allow organizations to visualize the effects of changes on their supply chain. Optiant provides ERP solutions that allow organizations to establish efficient, consistent, and effective order- and supply management processes.

Real-Time Inventory and Terra Technology offer real-time supply chain forecasting solutions. The collaborative management strategy allows companies to share information and other resources. It can include performance indicators and knowledge sharing.

It is important to take into account a few things before you start to implement a demand-management strategy. These factors will help professionals understand the process better and keep their focus on the most important elements.

Leadership buy-in and support is crucial for demand management. Demand management is a collaborative process that requires input from all levels of management. Top executives and managers are responsible for making sure that everyone is on the same page. The success of the initiative is also dependent on the participation of those at lower levels.

There are many applications available that can assist organizations in implementing a demand/supply planning. However, these key points should be kept in mind.

Understanding the market and identifying the ideal customer is key to demand management. The organization must not only know who to target but also be able measure and analyze its results.

To be more agile, businesses must create a demand-management strategy that can easily be modified to meet changing needs. A well-designed plan will reduce supply chain disruptions and tactical forecast errors. Demand management can be used to develop and implement strategic and portfolio plans.

FAQ

What is the responsibility of a logistics manager?

Logistics managers ensure that goods arrive on time and are unharmed. This is done using his/her knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

What are manufacturing and logistic?

Manufacturing is the production of goods using raw materials. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

How important is automation in manufacturing?

Automating is not just important for manufacturers, but also for service providers. They can provide services more quickly and efficiently thanks to automation. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What skills do production planners need?

A production planner must be organized, flexible, and able multitask to succeed. You must also be able to communicate effectively with clients and colleagues.

What is the role and responsibility of a Production Planner?

Production planners ensure all aspects of the project are delivered within time and budget. They ensure that the product or service is of high quality and meets client requirements.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

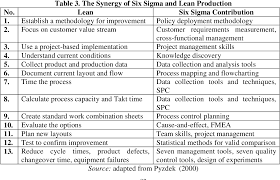

Six Sigma: How to Use it in Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma's primary goal is to reduce variation from the average value of production. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If it is too large, it means that there are problems.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. It is important to identify whether the variations are random or systemic. Random variations happen when people make errors; systematic variations are caused externally. If you make widgets and some of them end up on the assembly line, then those are considered random variations. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you've identified the problem areas you need to find solutions. You might need to change the way you work or completely redesign the process. Test them again once you've implemented the changes. If they don’t work, you’ll need to go back and rework the plan.