The Great Recession saw 166,000 jobs being lost by Ohio manufacturing companies. While the manufacturing sector in Ohio has rebounded, it has been slower than other states. Ohio's manufacturing sector is still at a lower level than it was before the recession.

Ohio's drop in manufacturing jobs is due largely to the rise of European and Japanese manufacturing competition. Manufacturers have had to improve their technology and cut labor costs. Global economic conditions have been difficult, leading to job losses.

Ohio's current workforce crisis is a significant challenge for manufacturers. However, the state has several initiatives to address the skill shortage. These initiatives are fragmented and siloed and don't address all the workforce issues manufacturers face. The Ohio Governor's Office of Workforce Transformation released a special report about the workforce shortage. It recommended greater collaboration between businesses and educators. However, the report discovered a gap between business and school needs.

Ohio's workforce has many faces and is diverse. Manufacturing workers are less likely not to be represented by unions than workers in other industry sectors. However, unionized manufacturing jobs offer solid benefits and livable wages.

Ohio's manufacturing industries are a major contributor of the state's economy. Interstate highways, railways and inland waterways allow manufacturers to efficiently distribute goods. In addition, the state ranks as a top exporter. Private investors will also be attracted by the state's natural-gas production.

While the state has gained 50,000 manufacturing job opportunities over the past four years of his administration, Kasich's tenure in office has seen slow job gains. Manufacturing job gains averaged 7 per cent in Kasich's first three years. Manufacturing jobs have declined by 1,771 in the past two years. These losses are due to the slowing global economy, the auto sector, and low global demand.

Ohio is a top exporter for goods. The top export markets are the U.S.A., Canada, Mexico and the U.K. In the past year, exports decreased by $1.4 Billion. Ohio manufacturers continue to face a major problem with trade policy. While changes in trade policy can help workers in specific industries, the full range of challenges will be addressed only by policymakers.

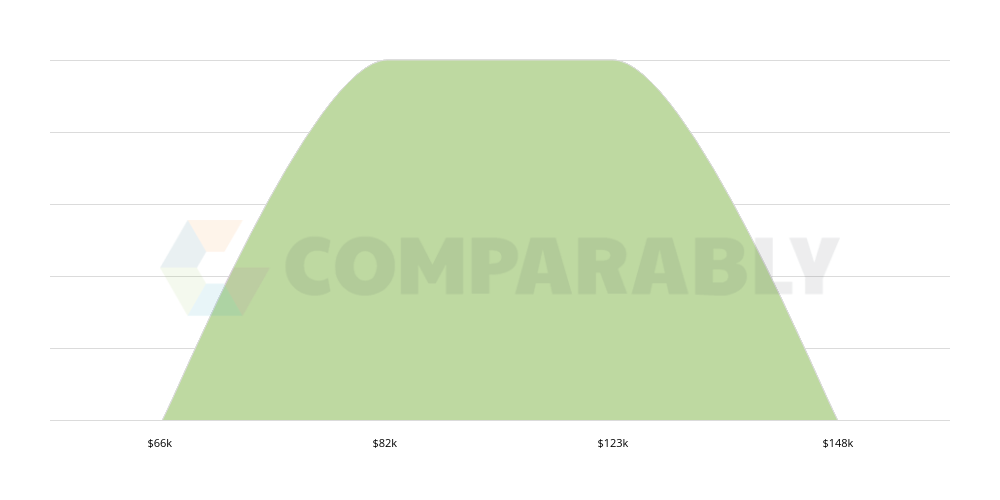

Ohio's primary industry is still manufacturing. Manufacturing jobs are among the most lucrative for semi-skilled workers who have not completed post-secondary education. But wages in Ohio have not kept pace with the production. Although manufacturing jobs pay higher than other occupations in Ohio, they are not enough for middle-class lifestyles.

Ohio's manufacturing workforce includes a variety of workers. Manufacturing industries in Ohio have been diversifying to meet the needs of the rest. Ohio's economy has changed to be more service-oriented. Manufacturing no longer is the main employer. Manufacturers are now focusing on developing future skills and international exposure.

FAQ

What are the responsibilities of a production planner

Production planners ensure all aspects of the project are delivered within time and budget. A production planner ensures that the service and product meet the client's expectations.

What is the importance of automation in manufacturing?

Automation is essential for both manufacturers and service providers. Automation allows them to deliver services quicker and more efficiently. It also helps to reduce costs and improve productivity.

What are manufacturing and logistic?

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It is about eliminating defects and waste from all stages of the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing practices are widespread in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow - Make sure work runs smoothly without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. To increase their competitiveness, many businesses have turned to lean manufacturing. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. It involves continuous improvement of processes, people, and tools.