Lean to agility is a great method to reduce waste, increase team productivity and increase efficiency. This approach focuses on prioritizing work, eliminating waste, and empowering scrum masters and teams to do the rest. Agile teams should be empowered with the ability to act as product owners. They also need to have servant leaders who are committed and dedicated to their projects' success.

Time-to-market

One of the most important measures of product success is how long it takes to go from ideation to final release. The faster you can capture market share, revenue and profits, the shorter it is. Companies need to know their development processes, and how they use them. They can then refine their processes to achieve their goals and use their capabilities to increase time-to-market.

To reduce the time to market a new product, outsourcing can be used as a way to cut down on time. You can also reduce the time required to market a new product by creating a network of trusted support partners. This can reduce risk while sharing resources.

Iteration

Iteration is an important element in agile software development. Iteration emphasizes the importance small, manageable steps that can easily be tested and evaluated sooner than a whole process. The chances of success are greater for features that are more detailed. The process is usually time-bound. An iteration's final product should be available and running. To do this, it must be integrated, tested, and deployed on an internal server.

Iterations enable teams to review their backlog and resolve risks and issues that weren't previously discovered. The aim is to make each iteration better than the one before. Developers may refactor or add new features to existing features. This continues until the product's release is complete.

Collaborative processes

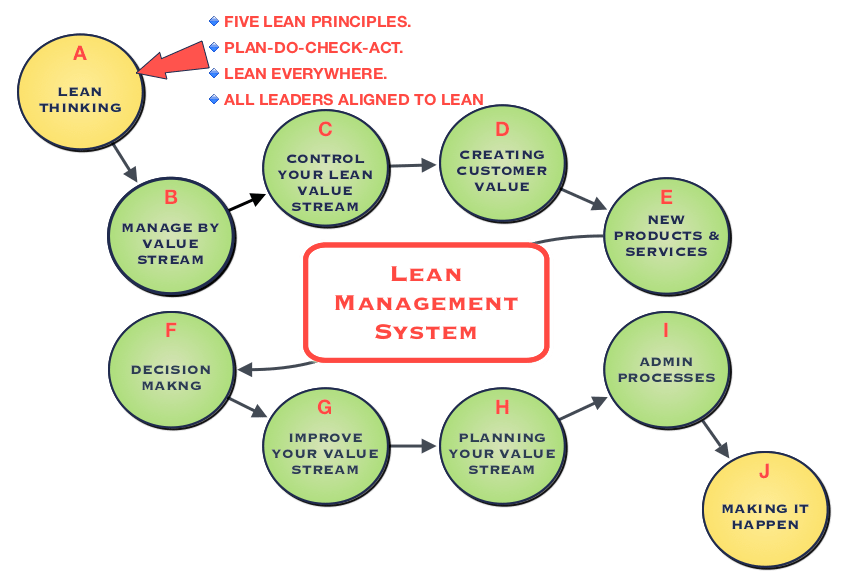

Agile Manifesto stresses the importance of collaboration between developers and business stakeholders. This allows teams prioritize work based off business goals. Lean processes also promote a value stream - the end-to-end list of actions that produce the product or service customers desire. While these approaches may seem similar, there are important differences.

Agile is more flexible than Lean. Lean UX teams use Lean instead of rigid project management tools. They work in small groups and scale up quickly to reach a goal. Agile is a system with small-world networks and deliverables. It also emphasizes autonomy exploration and collaboration. An agile approach is required for scaling from one project to multiple projects.

Getting user research into agile teams

Agile teams are increasingly including user research in their processes. This mindset is becoming increasingly common in product design, but it's also being applied to other areas. Teams are becoming more aware of the importance usability and user experience and the need to do quick and flexible research. Agile teams apply agile thinking to identify processes that are connected to the product backlog in order to get user-centric research at the forefront of development.

It is essential that user research workflows are simpler and more democratic. This involves creating repeatable templates for user research that non-practitioners could use to run their tests. These templates should address the most frequently asked questions and be applicable to all stages of product development. Teams can also use UX platforms that provide preloaded templates and automated workflows to ensure consistent results.

Creation of value

Even though it is a simple concept, the idea of value creation can seem a little strange. It is possible to create value with either a narrower scope or a more expansive one. But, in neither case is it completely binary. In certain cases, a smaller scope creates a small value, and a larger scope generates more value. Still, the concept of a full scope can be useful.

Lean and agile aim to provide a customer with a high-quality, focused product. Combining both these methods can help companies deliver a superior product quicker. This reduces overhead, empowers employees and allows them to concentrate on the customer.

FAQ

What is the responsibility of a production planner?

Production planners ensure all aspects of the project are delivered within time and budget. A production planner ensures that the service and product meet the client's expectations.

Can we automate some parts of manufacturing?

Yes! Yes. The Egyptians invented the wheel thousands of years ago. Today, robots assist in the assembly of lines.

Robotics is used in many manufacturing processes today. These include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

Manufacturing can also be automated in many other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

What skills does a production planner need?

Production planners must be flexible, organized, and able handle multiple tasks. Communication skills are essential to ensure that you can communicate effectively with clients, colleagues, and customers.

How can overproduction in manufacturing be reduced?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce the time needed to manage inventory. We could use these resources to do other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban Board is a visual display that tracks work progress. A Kanban system allows work items to move through several states before reaching their final destination. Each state has a different priority level.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows you to keep work moving along while making sure that no work gets neglected. With a Kanban board, managers can see exactly how much work is being done at any given moment. This allows them the ability to adjust their workflow using real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing emphasizes eliminating waste in all phases of production. Any product that isn't adding value can be considered waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Packaging that is not necessary

-

Exceed materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to Use Just-In-Time Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. It's the process of obtaining the right amount and timing of resources when you need them. This means you only pay what you use. Frederick Taylor developed the concept while working as foreman in early 1900s. He noticed that workers were often paid overtime when they had to work late. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. You can anticipate problems and have enough equipment and people available to fix them. You won't have to pay more for unnecessary items.

There are different types of JIT methods:

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will enable you to keep track of how much material is left after you use it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows for you to anticipate how much you can sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based JIT is the most widespread form. Here you can allocate certain resources based purely on demand. You will, for example, assign more staff to deal with large orders. If you don’t have many orders you will assign less people to the work.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT : This is the newest type of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, your goal is to add value to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. This is used to increase production and minimize inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It's the process of scheduling delivery of components immediately after they are ordered. It's important as it reduces leadtimes and increases throughput.