During the Great Recession, the manufacturing industry lost nearly 2 million jobs. While employment in the industry has regained some of its lost ground, job growth has remained subdued. Manufacturing faces many challenges, including higher prices and tariffs as well as the diminishing impact of 2017 corporate tax cuts. The slow global growth is compounding these problems.

The manufacturing sector is varied and wide-ranging. This industry has many job opportunities. These jobs often require little to no hands-on labor. For example, manufacturing workers are responsible for the assembly and packaging of a variety of products for sale. They are responsible for monitoring production and transporting raw materials. In addition, there are jobs in science, technology, and math.

There are jobs in advanced manufacturing as well as traditional manufacturing. These jobs are very technical, so the skills required for them could be used in other industries. Many employers offering advanced manufacturing jobs may offer training and benefits such as apprenticeships. They might also offer great wages. But they are not easy to find. Employers may find it attractive to offer advanced manufacturing positions in the event of a shortage of labor.

One of the most exciting aspects of the manufacturing industry is the diversity of roles. Workers may be employed in power plants, manufacturing facilities, or bakeries. Additionally, they might be responsible for administrative tasks like managing a production crew. They may also work in food processing facilities, including meat cutters, fish cutters, and batchmakers.

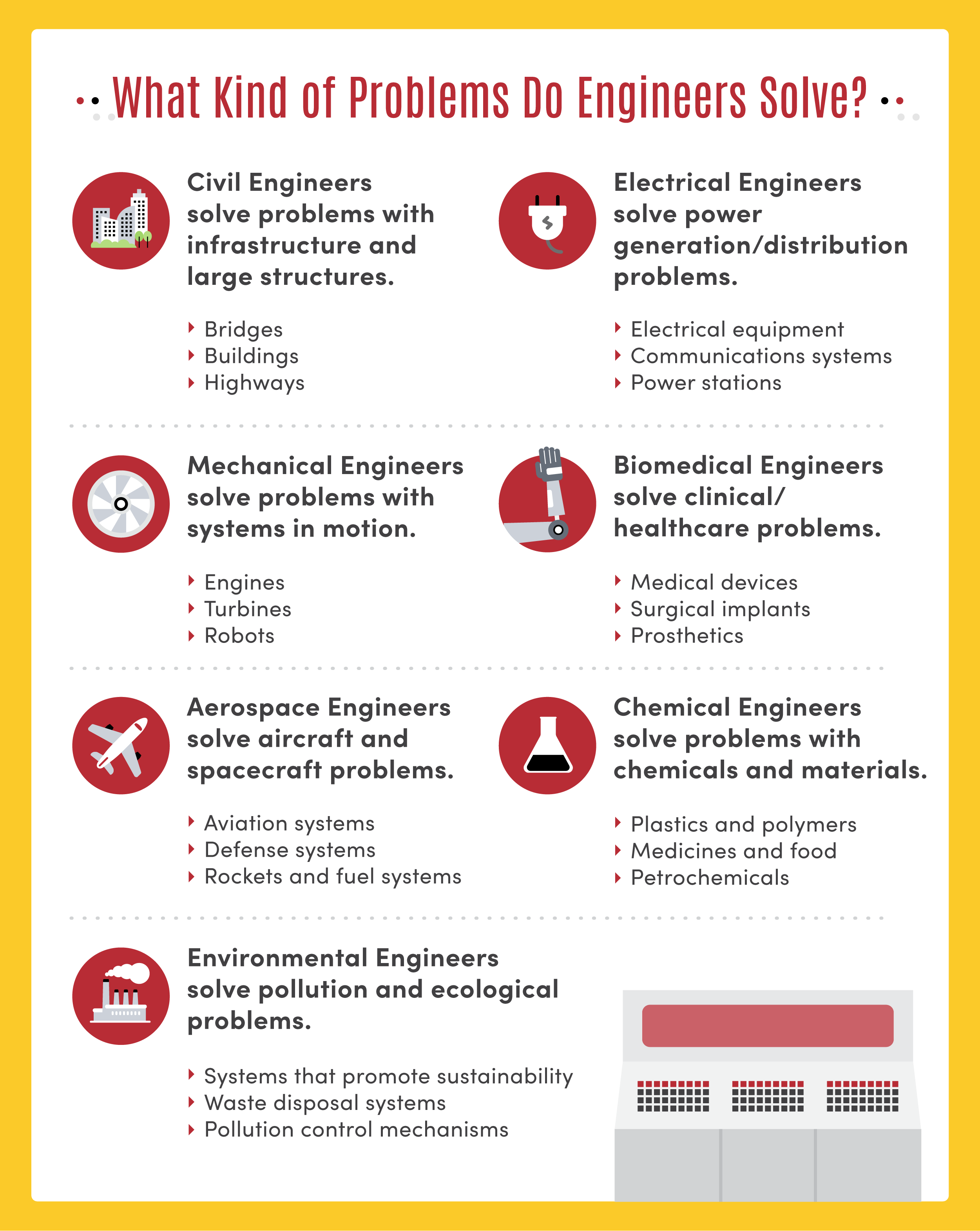

While there are many occupations to choose from in the manufacturing industry, the best opportunities are often found in professional and managerial roles. A high school diploma is required for most production-related occupations. A bachelor's or master's degree is sometimes preferred. For manufacturing jobs where workers must work with plant machinery, a technical education is desirable. Recent growth has also been seen in science and technology jobs.

Producing jobs is a great place for you to showcase your talents. If you are looking for a career in film, video, or animation, you might consider offering to work for free at a production company in exchange for references. This can be an invaluable experience that can lead you to valuable connections. However, you should also research the production industry in your area to determine whether there is demand for your skills. You also need to find out if you're qualified for an entry level production job.

Many research studies indicate that the production industry has experienced a large increase in the number temporary workers. The Great Recession was a large factor in this rise. The use of temporary workers in the construction and healthcare sectors has declined over the past five year, while the number of people working in the computer and mathematical fields has increased. However, manufacturing's use has increased nearly twice in the same time frame.

A variety of other jobs can also be found in the production industry such as sound technicians or audio engineers. Additionally, there has been a slight increase of women in manufacturing jobs. In the past year, the proportion of women employed in the manufacturing industry has increased by 5.3 percent. The industry's women workers have not seen an increase in their numbers at the same time as men. This is partly due to the fact that the majority of people working in the industry are assistants.

FAQ

Why automate your factory?

Automation has become increasingly important in modern warehousing. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses must adapt quickly to meet changing customer needs. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automation warehouses can bring many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

Increases efficiency of workers

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reduces downtime and improves uptime

-

Ensures quality products are delivered on time

-

Removes human error

-

It helps ensure compliance with regulations

What are the 4 types of manufacturing?

Manufacturing is the process of transforming raw materials into useful products using machines and processes. It can involve many activities like designing, manufacturing, testing packaging, shipping, selling and servicing.

What are the responsibilities of a logistic manager?

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is achieved by using their knowledge and experience with the products of the company. He/she should ensure that sufficient stock is available in order to meet customer demand.

What does it take for a logistics enterprise to succeed?

It takes a lot of skills and knowledge to run a successful logistics business. You must have good communication skills to interact effectively with your clients and suppliers. It is important to be able to analyse data and draw conclusions. You will need to be able handle pressure well and work in stressful situations. To improve efficiency, you must be innovative and creative. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

To meet tight deadlines, you must also be efficient and organized.

What are the products and services of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians make sure that the right product arrives at the right place at the correct time and in safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

How can we reduce manufacturing overproduction?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. We could use these resources to do other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban board, a visual display to show the progress of work, is called a Kanban board. Kanban systems allow work items to move through different states until they reach their final destination. Each state represents a different priority.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This allows them the ability to adjust their workflow using real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that doesn't add value to the product is considered waste. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Packaging not required

-

Excess materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

Are there ways to automate parts of manufacturing?

Yes! Yes. Automation has been around since ancient time. The Egyptians invent the wheel thousands of year ago. Robots are now used to assist us in assembly lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Manufacturing can also be automated in many other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes the elimination of defects and waste throughout the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing can be found in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five principles are the basis of lean manufacturing:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Many economists believe lean manufacturing will play a major role in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

It can be applied to any aspect of an organisation. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types in lean manufacturing

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. It involves continuous improvement of processes, people, and tools.