Supply Chain Management Review is a great resource for business owners looking for the most recent trends in supply chain management. The magazine is based in the U.S. and has been publishing for nearly a decade. It covers issues such as the changing nature business models and the role of technology. The publication offers an in-depth look at the industry, and is especially relevant to companies that manage a large supply chain.

The final stage in supply chain management is manufacturing

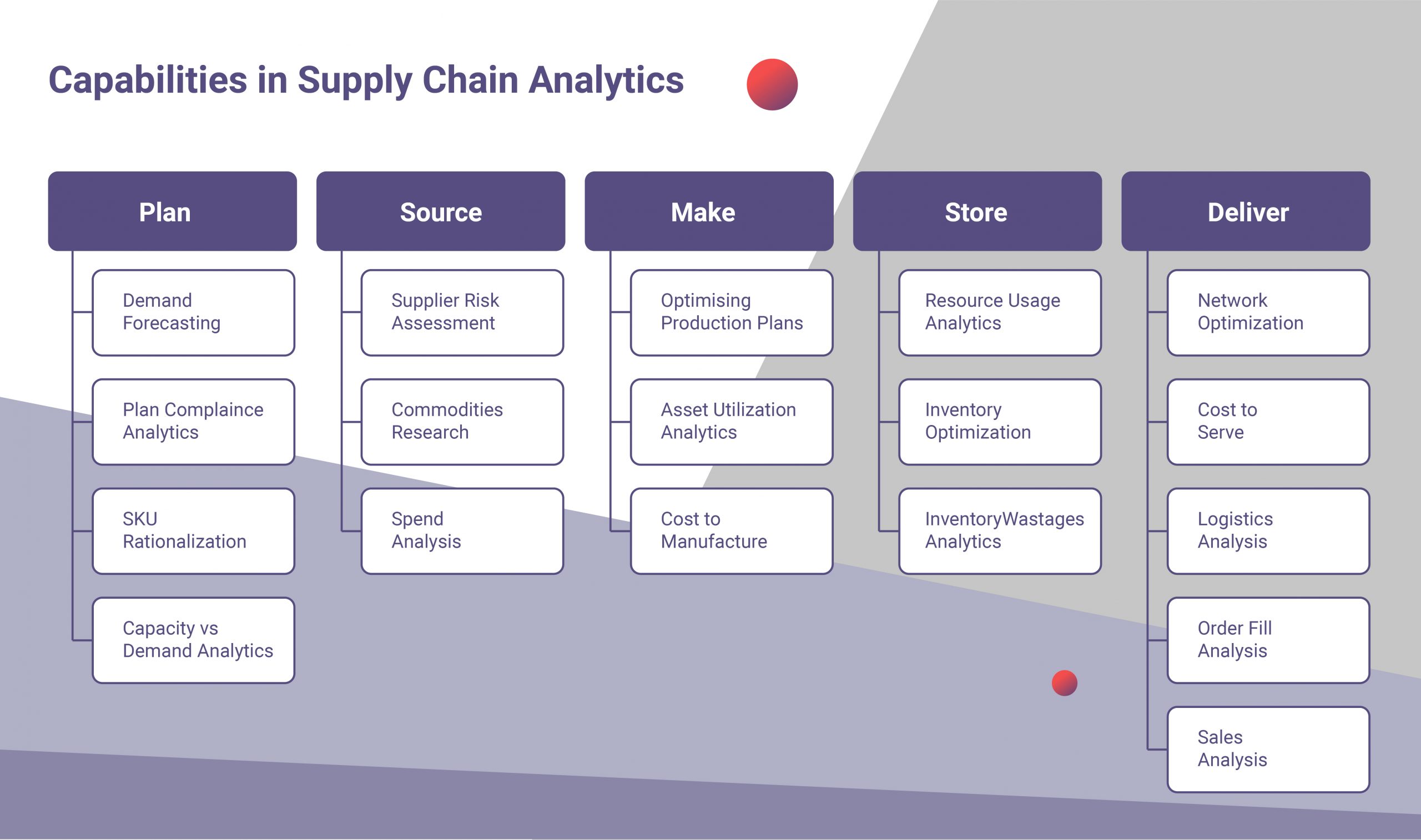

Supply chain management is a complicated process that involves five key elements. They include planning, sourcing raw ingredients, manufacturing, delivery and return, and logistics. To avoid costly bottlenecks companies need to be competent in all these areas. Manufacturing is essential for perishable goods because it requires prompt delivery.

Reverse logistics

Reverse logistics management is vital to the bottom line of a company. This service allows companies use their existing infrastructure to lower costs and increase efficiency. Reverse logistics can improve a company’s image by enabling it to employ sustainable business practices. However, reverse logistics is not without its challenges.

Flexible model

Flexible supply chains can be a great way for businesses to meet consumer demand, whether it is high or low. It relies on part segmentation, accurate stocking algorithms, and flexible planning, which includes incorporating automation on factory floors. For example, Staples, which manufactures writing utensils, anticipates a surge in demand during the back-to-school season and stocks up on supplies throughout the year.

Agile model

A review of the Agile model for supply chain management can be a great way to help organizations make substantial changes and ensure that your supply chain is responsive to new developments. Changes, such as the loss of a significant manufacturing partner or logistical block, can lead to significant delays, but an agile supply chain can overcome these challenges quickly. It also gives visibility to supply chain stakeholders, which allows them to improve the efficiency of their process. It also allows companies to outsource specific supply chain segments, which results in lower costs. It allows businesses to plan ahead and reduce their stock levels.

Model of fast-chain

A fast chain model for supply chain management emphasizes speed and responsiveness, and is ideal for companies that change product lines frequently and are competing for the same customers. This model is characterized by efficient inventory management and maximizing the use of production equipment and labor. It is best suited for businesses that produce trendy items with short life cycles. This model is also a good fit for businesses who need products to be on the market quickly.

Supply chain management: Ethics

Companies have made ethics in supply chain management a priority because it affects business performance. The issue affects more than factories and workers: environmental, social, and labor issues are common problems faced by supply chain companies. A number of initiatives have been taken by organizations in order to promote ethical supply chains.

FAQ

What are the responsibilities for a manufacturing manager

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They must also be alert to any potential problems and take appropriate action.

They should also be able and comfortable communicating with other departments like sales and marketing.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

What is the best way to learn about manufacturing?

The best way to learn about manufacturing is through hands-on experience. But if that is not possible you can always read books and watch educational videos.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. Knowing about manufacturing processes will help you understand how logistics works.

What does it mean to be a manufacturer?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are those who purchase these products. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They produce goods from raw materials by using machines and other machinery. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation invented the 5S strategy in 1954. It improves the work environment and helps companies to achieve greater efficiency.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. This means that every day tasks such cleaning, sorting/storing, packing, and labeling can be performed. Because workers know what they can expect, this helps them perform their jobs more efficiently.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step involves a different action which leads to increased efficiency. Sorting things makes it easier to find them later. When items are ordered, they are put together. Next, organize your inventory into categories and store them in containers that are easily accessible. Finally, label all containers correctly.

Employees must be able to critically examine their work practices. Employees need to be able understand their motivations and discover alternative ways to do them. To be successful in the 5S system, employees will need to acquire new skills and techniques.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. They will feel motivated to strive for higher levels of efficiency once they start to see results.