Six-Sigma and Lean both offer complementary methods for improving processes. They both use the same tools for problem-solving, but each has different strengths and weaknesses. Six-Sigma refers to a statistical control technique. Lean, on the other hand, starts with the assumption that a product should add value to its customers, not just make it. Lean is about reducing waste and improving the quality of products as they are being made.

Problem solving in PDCA

While there are differences between DMAIC and PDCA, both approaches are based on DMAIC. The PDCA cycle requires more planning and analysis. Unlike DMAIC, PDCA is not effective for solving urgent problems. This approach requires a problem solver with technical skills. Six Sigma will require a problem-solving team lead who is a Six Sigma "green belt" certified practitioner.

Six Sigma follows a cycle first introduced by W. Edwards Deming back in 1950s. It was developed to be used alongside continuous improvement methods to aid in rebuilding Japan's economy. The P (Plan) stage requires real data to be gathered and a clear mission. After the PDCA stage, the group must choose a solution.

Process maps

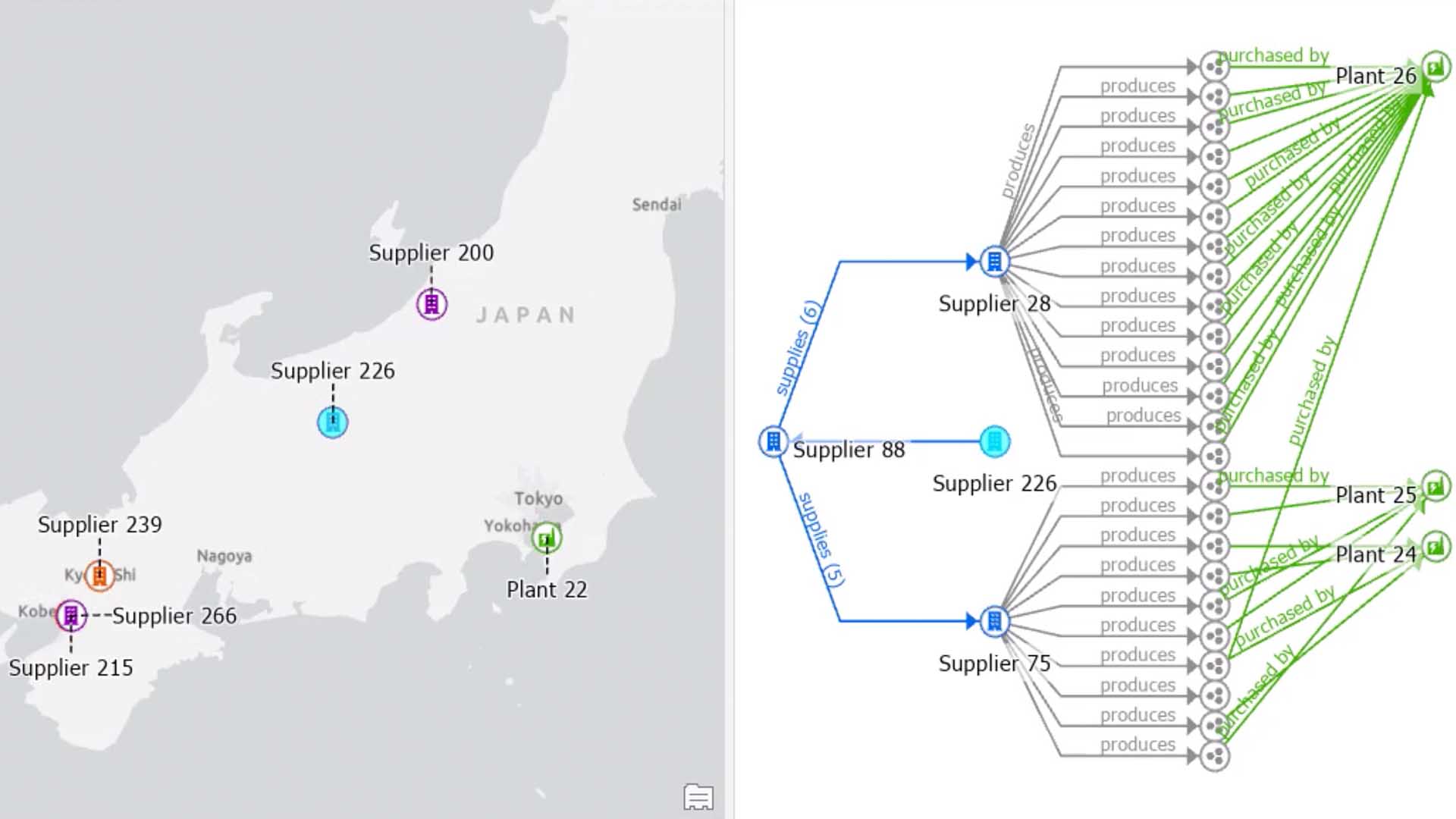

The way that each approach describes the process is a key difference between Six Sigma and Lean processes maps. Both emphasize defining a process in detail, but each methodology focuses on different aspects of the process. Lean, for instance, involves mapping actual processes as opposed to standard operating procedures. Consider the main activities, decisions, as well as sources of approval, when creating process mappings. Consider areas that use multiple methods, factors, and other obstacles. Make sure you match the roles and look at the process flow.

To illustrate the process flow, a process map must include steps, symbols, or arrows. Every process should be reviewed several times to verify that it accurately represents the actual process. Also, a process map should include the date it was created and who to contact if there are any questions. Process maps can be a great way to improve any process. However, they can be complicated.

Analyse Cause and Effect

Six Sigma and lean project managing techniques use statistical analysis and stochastic optimising. The Cause and Effect Matrix relates each step in a process to its outputs and inputs. The customer requirements are listed by importance and then inputs and outputs are ranked according their effect on the outcome. The ranking and key input variables should be established.

Although each technique may have its own set of benefits they are not all the same. Lean Six Sigma uses a process improvement methodology that is based on Frederick Winslow Taylor's Principles of Scientific Management. Taylor saw business processes as interconnected processes and workflows. Taylor advocated reducing variation and also minimizing waste. Six-Sigma and Lean complement each other in the reduction of waste.

Eliminating Variation

Variation is a part of any manufacturing process. Variability can lead to uncertainty about the final outcome. It is important to maintain consistency in order to deliver professional results. Predictable output is achieved by eliminating variation in Six Sigma and Lean manufacturing processes. While some variation is acceptable, too much can lead to costly repairs and rework. The best way to manage variation is to identify the root cause.

Look for variations at decision points first. Process maps show decision points and are represented by diamonds. Six Sigma teams can begin by identifying decision points, and then start eliminating variations. This information is obtained directly from the Six Sigma process owner. The Six Sigma group cannot focus on a process that is not governed by a standard process if it's owner. The Six Sigma team may not have enough technical capacity to modify the process map in this instance.

FAQ

How does a Production Planner differ from a Project Manager?

The difference between a product planner and project manager is that a planer is typically the one who organizes and plans the entire project. A production planner, however, is mostly involved in the planning stages.

What are the four types in manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. It can involve many activities like designing, manufacturing, testing packaging, shipping, selling and servicing.

Why automate your warehouse

Automation has become increasingly important in modern warehousing. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses must be able to quickly adapt to changing demands. To do so, they must invest heavily in technology. Automation of warehouses offers many benefits. These are just a few reasons to invest in automation.

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety is boosted

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

Increases efficiency of workers

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

High quality products delivered on-time

-

Eliminates human error

-

Assure compliance with regulations

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. This is done through forecasting demand and identifying production capacities.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

What type of jobs is there in logistics

There are many kinds of jobs available within logistics. Here are some:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transportation drivers - They drive trucks and trailers to deliver goods and carry out pick-ups.

-

Freight handlers – They sort and package freight at warehouses.

-

Inventory managers - These are responsible for overseeing the stock of goods in warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others - There are many other types of jobs available in logistics, such as transportation supervisors, cargo specialists, etc.

What are manufacturing and logistics?

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

How does manufacturing avoid bottlenecks in production?

You can avoid bottlenecks in production by making sure that everything runs smoothly throughout the production cycle, from the moment you receive an order to the moment the product is shipped.

This includes planning to meet capacity requirements and quality control.

This can be done by using continuous improvement techniques, such as Six Sigma.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It is focused on creating consistency and eliminating variation in your work.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to use 5S to increase Productivity in Manufacturing

5S stands for "Sort", "Set In Order", "Standardize", "Separate" and "Store". Toyota Motor Corporation developed the 5S method in 1954. It improves the work environment and helps companies to achieve greater efficiency.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. This means that every day tasks such cleaning, sorting/storing, packing, and labeling can be performed. These actions allow workers to perform their job more efficiently, knowing what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step requires a different action, which increases efficiency. If you sort items, it makes them easier to find later. When you arrange items, you place them together. Next, organize your inventory into categories and store them in containers that are easily accessible. Make sure everything is correctly labeled when you label your containers.

Employees will need to be more critical about their work. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. They must learn new skills and techniques in order to implement the 5S system.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.